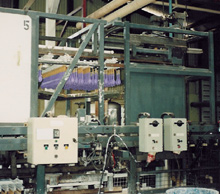

Microprocessor controlled automatic batch dipping plant

for continuous production of promotional and novelty/toy balloons

The plant is designed for high volume, low cost output, whilst retaining flexibility of operation to allow changes in colours, shapes and sizes on line, without down time.

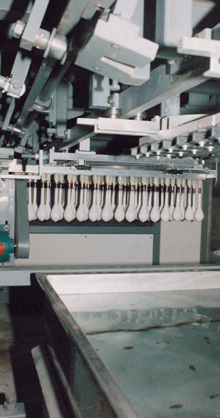

Robustly constructed for reliability and minimum maintenance the plant comprises a two deck conveying system combined in a closed loop in which groups (batches) of formers are conveyed progressively along lower and upper horizontal tracks. All movements are controlled and interlocked by a programmable electronic command system which also provides diagnostic read-out in the event of mal-function.

Description of balloons

Description of balloons

A good balloon has the following conditions

1. regular peripheral wall thickness

2. good end gelation

3. pinhole free

4. good bead rolling

5. "favourable taste"

The above are controlled by

1. surface tension control of coagulant and good anti-settling of 'chalk', even speed immersion and withdrawal with still liquid surface.

2. correct compound viscosity and correct chemical stability

3. clean formers and efficient filters

4. good step back of film thickness, well-leached film, dryness state.

5. chemically friendly formula, well-leached film.

A good even latex film depends upon a good even coagulant deposit, which depends upon fast drying, even withdrawal speed from the coagulant. This means a hot coagulant and a hot former and with small time cycles leading up to the coagulant dip, it is important not to lose heat necessarily after the stripping.

A good even latex film depends upon a good even coagulant deposit, which depends upon fast drying, even withdrawal speed from the coagulant. This means a hot coagulant and a hot former and with small time cycles leading up to the coagulant dip, it is important not to lose heat necessarily after the stripping.

* Because of "intended health regulations", leaching is more important than ever, and ideally should come before beading. But because some drying - not too much - is necessary, this design may not accommodate this situation.

What has to be accepted, is that the machinery provides as much satisfaction as possible especially in the sense that this is then advertising a good machine builder.

Technical Data

Plant Dimensions L x W x H = 22-24 M x 4.1 M x 4.0 M

Plant Dimensions L x W x H = 22-24 M x 4.1 M x 4.0 M

(depending on new machine in development)

Production Capacity 8,400 - 19,600 pcs/hr, dependent on size

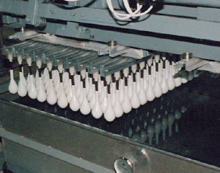

Formers (to fill plant) Semi-flat type for 12" Balloons 8,400 pcs

Semi-flat type for 10" Balloons 10,000 pcs

Semi-flat type for 8" Balloons 11,600 pcs

Novelty Balloons "AIRSHIP" 13,200 pcs

Novelty Balloons "PENCIL" 19,600 pcs

Maximum Length of Formers 267mm

Groups of Formers (Trollies) 40 (new machine 44-46)

Former Bars 400 (new machine 440-460)